Description

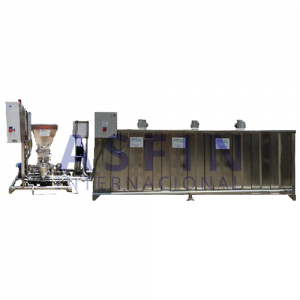

In-Line Flocculant Preparation Equipment for 1000 kg bags.

Consists of a water booster pump station, a humidification unit and three in-line tanks: Preparation, Maturation and Dosing. Fully automatic operation. Unlike the EPFCL25, it has a structure to hang super bags by means of a hoist (not included). It is manufactured in T304 or T316 stainless steel.

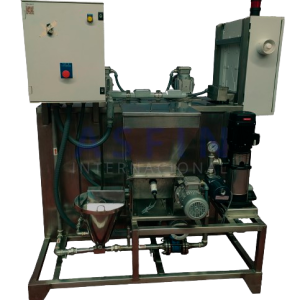

The humidification unit consists mainly of: a pneumatic valve, a flowmeter, a hopper with a screw shaft design, a humidification cone, a pressure gauge, an ejector, a spring check valve, a gate check valve and a control panel.

Each tank has a geared motor and a two-bladed agitator. The dosing tank has three level electrodes (high, low and low low).

The essential supplies for its operation are: Electrical power at 220 or 440 VAC, Compressed air at 90 psi, Water and ASFLOCMR Polymer.

Our equipment has a visual alarm (turret) and an audible alarm (90 dB) that warns us when any input is missing or there is a failure in any of the motors.

The recommended capacities for this equipment are 150 LPM and 250 LPM.

This equipment is recommended for all types of industry.