Problem

ASFIN INTERNACIONAL has Flocculant Preparation Equipment (EPF) installed in different mineral benefit plants in Mexico. It is important to carry out preventive maintenance on this equipment in order to guarantee its correct and continuous operation.

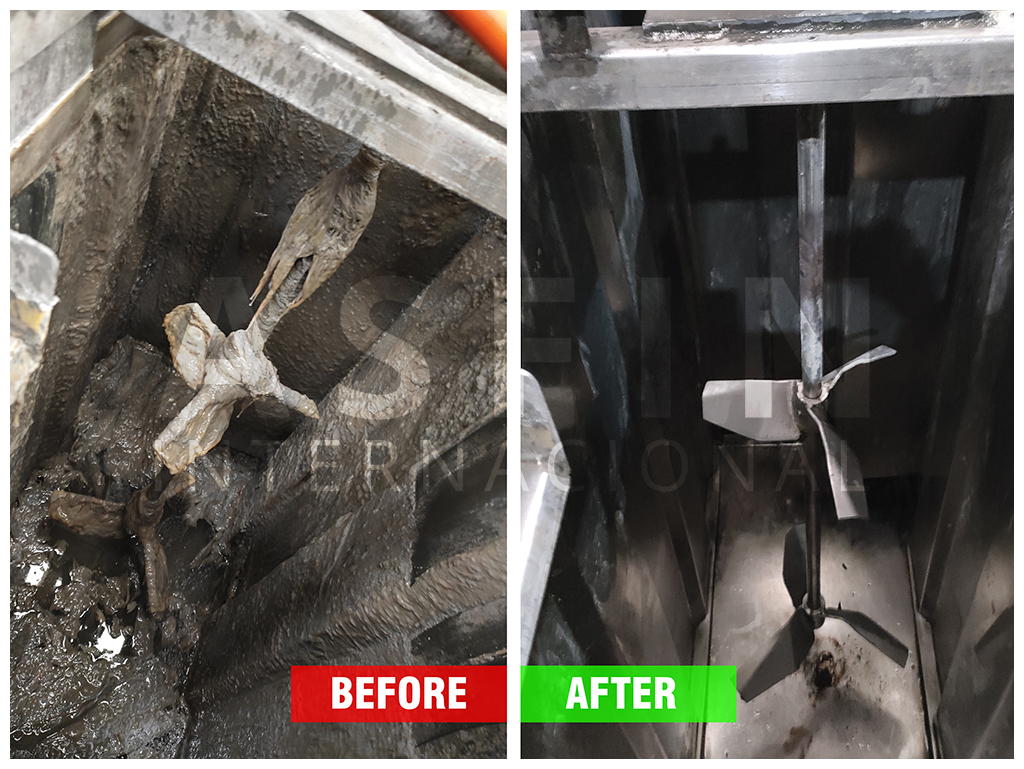

The client asked us for immediate intervention to provide service to his two EPF’s which were in critical condition.

The client asked us for immediate intervention to provide service to his two EPF’s which were in critical condition.

Solutions and results

Without delay, the following activities were carried out:

- De-energization of the Flocculant Preparation Equipment and emptying of the tanks

- Review and cleaning of control cabinets

- Inspection and cleaning of the cone, ejector, flowmeter, worm motor, booster pump, pipes and valves, of the humidification unit

- Interior and exterior cleaning of the Flocculant Preparation Equipment tanks, as well as the gear motors, agitators and level electrodes

- Operation and performance tests

The equipment was delivered in record time ready to operate for a minimum period of 12 months under normal operating conditions.

Benefits

- Ensure correct polymer preparation

- Ensure plant operation with flocculant

- Identify and prevent potential problems with equipment

- Provide longer useful life to EPF’s