Problem

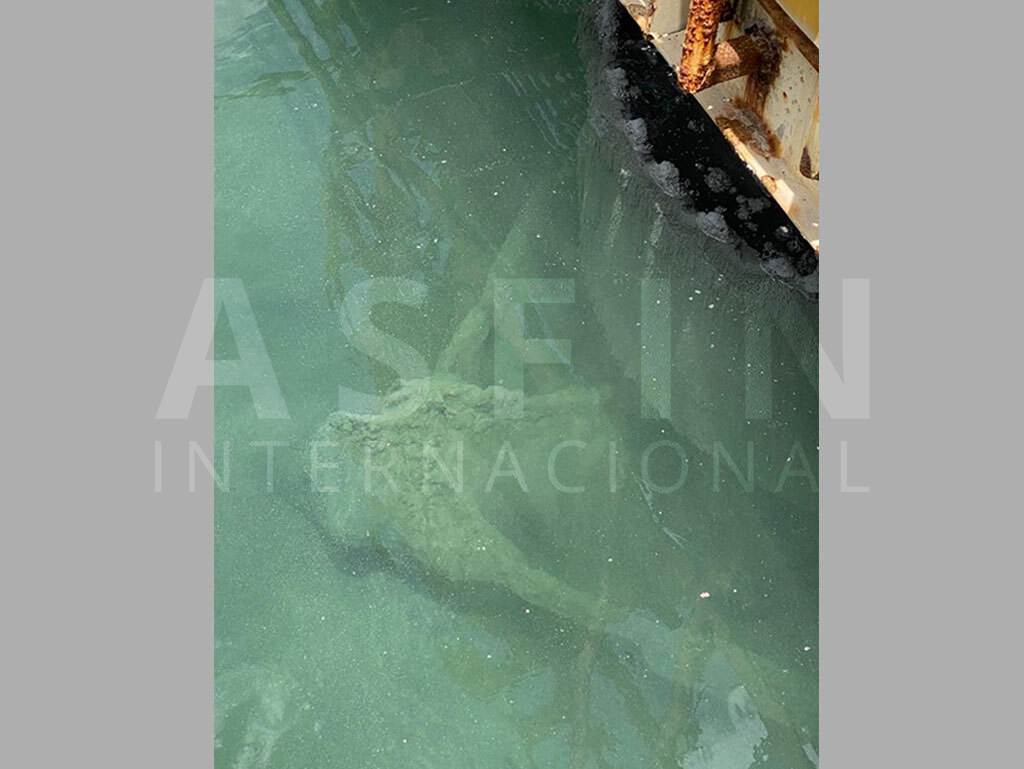

In leaching plants for Au and Ag extraction, oxides are processed. It is critical that the downstream scrubbers operate optimally, so that scrubber No. 1 has as few solids as possible.

The client visited could not achieve this condition and in the following stages of their process, was considerably affected.

When turbidity measurements were taken in the overflows of their scrubbers, it was observed that the values were high due to poor sedimentation.

The client visited could not achieve this condition and in the following stages of their process, was considerably affected.

When turbidity measurements were taken in the overflows of their scrubbers, it was observed that the values were high due to poor sedimentation.

Solutions and results

We proceeded to evaluate our medium, high and super high molecular weight anionic ASFLOC™ flocculants in laboratory tests.

We noticed that our ASFLOC™ 034 SH at equal doses of 746 ml/min total increased the sedimentation rate by 5% and reduced turbidity by 50% compared to the reagent used.

Subsequently, an industrial test was carried out, which turned out to be totally favorable.

Since then, our customer has been operating his washer No. 1 with turbidities around 2 NTU and works with a 30% lower consumption than before.

We noticed that our ASFLOC™ 034 SH at equal doses of 746 ml/min total increased the sedimentation rate by 5% and reduced turbidity by 50% compared to the reagent used.

Subsequently, an industrial test was carried out, which turned out to be totally favorable.

Since then, our customer has been operating his washer No. 1 with turbidities around 2 NTU and works with a 30% lower consumption than before.

Benefits

- Improved operation of downstream scrubber processes

- Reduced polymer consumption compared to the one used in the past

- Considerable savings in operating costs