Problem

Previously, the plant prepared the flocculant manually using a single dosing tank, which resulted in:

- Insufficient preparation times

- Formation of lumps in the flocculant

- Variations in concentration affecting the process

- Inconsistent reagent consumption

- Strong dependence on the operator in charge of the area

Solutions and Results

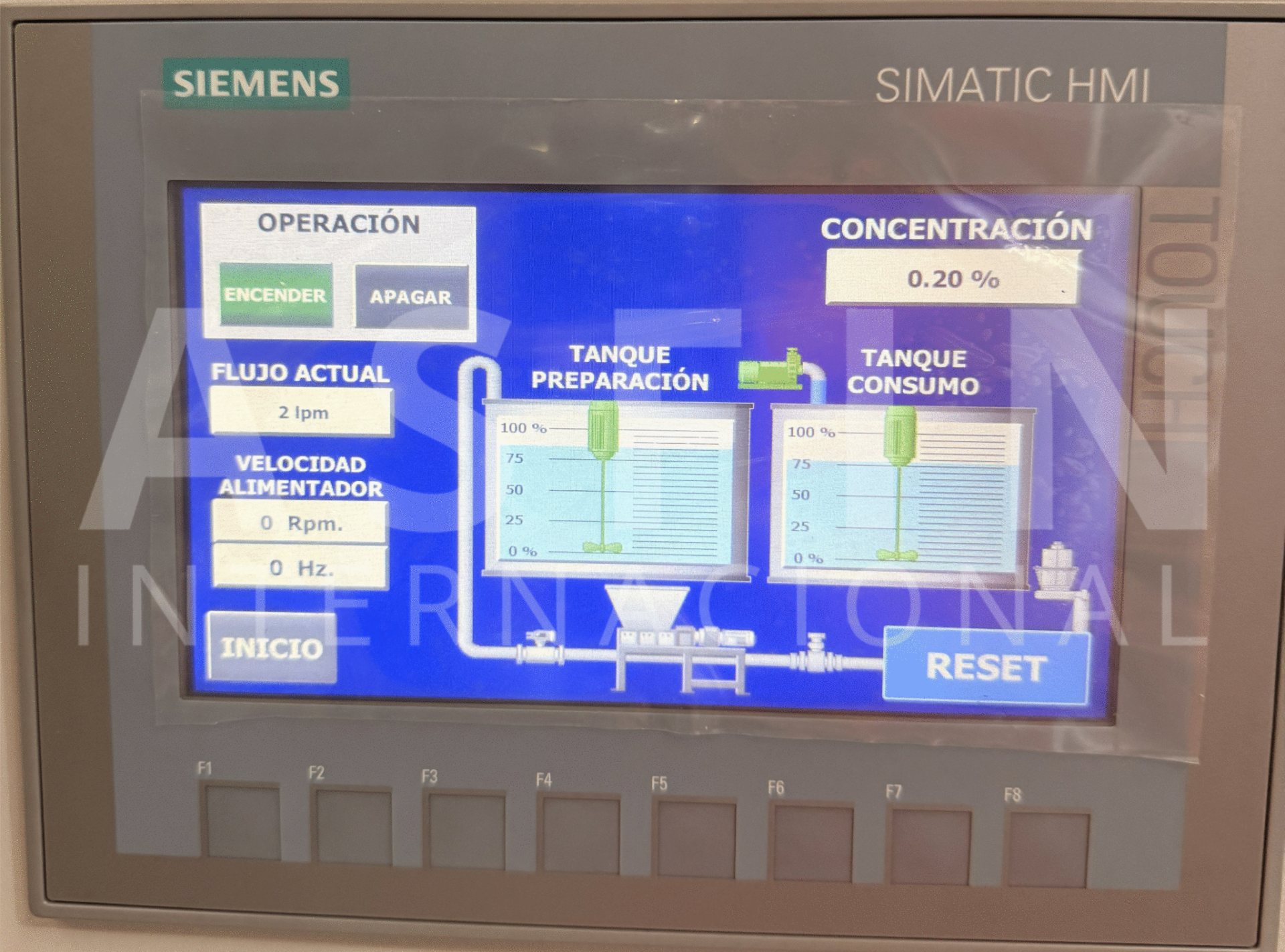

A dual moistening unit that could work with 25 kilograms bags and, 750 kilograms and 1,000 kilograms super bags, was designed. The system was integrated using an existing transfer pump and two ultrasonic level sensors (supplied by our company) into the existing 20 m³ preparation–maturation tank and 10 m³ dosing tank.

An ASFLOCTM Automatic Polymer Moistening Unit model UHF750/300/304/460, was manufactured and fully interconnected with the other equipment. Its PLC system enables real-time monitoring of tank filling and emptying, as well as transfer pump operation.

This automated system ensures efficient polymer preparation, optimizing the client’s resources while strictly adhering to their operational requirements.

Training was also provided to the plant’s operating personnel.

Benefits

- Resource optimization

- Reduced operator intervention

- Improved operational efficiency

- Significant reduction in operating costs