Problem

In mineral processing plants, tails thickeners are normally used to recover very good quality process water and sending the sludge to the tailing’s dams.

The client added a tails thickener to their process for which a “Flocculant Plant” was required to ensure the correct sedimentation of solids.

The client added a tails thickener to their process for which a “Flocculant Plant” was required to ensure the correct sedimentation of solids.

Solutions and results

We proceeded to evaluate the necessary components and their characteristics to meet the process requirements

The following ASFLOC brand equipment was supplied and put into operation:

The following ASFLOC brand equipment was supplied and put into operation:

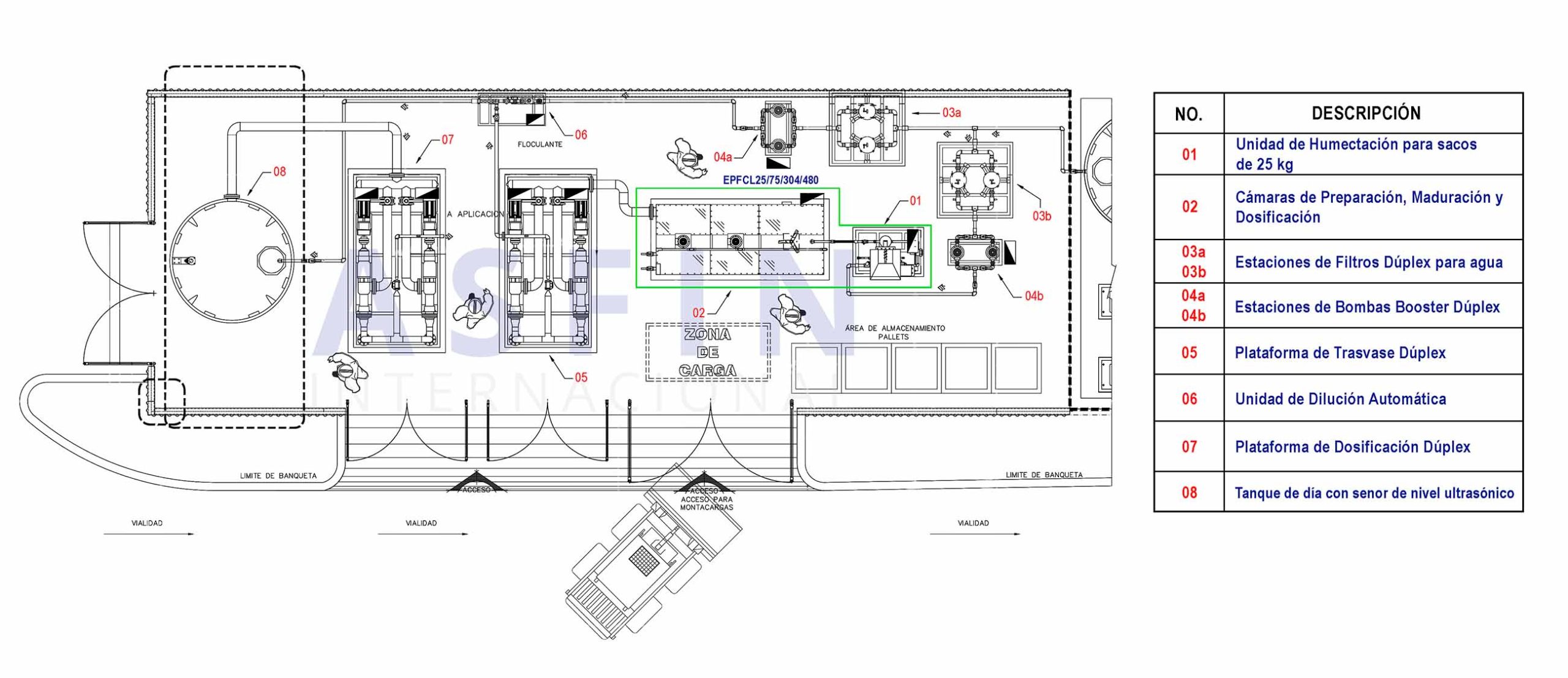

- A Flocculant Preparation Equipment model EPFCL25/75/304/480

- Two Duplex Filter Stations for water model EFIL12

- Two Duplex Booster Pump Stations for water model EBB200/80 of 200 LPM

- A Duplex Automatic Transfer Platform model PDOS-AUT200/60 of 200 LPM

- An Automatic Dilution Unit model UDIL-AUT300 of 300 LPM

- A Duplex Automatic Dosing Platform model PDOS210/60 of 210 LPM

- A 10 m3 day tank with ultrasonic level sensor

According to the arrangement shown below:

- Installation of interlocks to protect equipment against the lack of water or flocculant and motor failure

- The signals and variables of the Siemens PLC of the Flocculant Preparation Equipment and the Dilution Unit were integrated into the tails thickener control system

- Unit personnel were trained for the correct operation and equipment maintenance

Since then, our client operates this new part of their process satisfactorily.

Benefits

- Greater recovery of high-quality water

- Correctly and easier preparation, transfer, dilution and dosing of the flocculant, which translates into lower polymer consumption

- Automatic “flocculant plant” with continuous remote monitoring

- Greater efficiency

- Simple operation because only the polymer hopper needs to be filled

- Operating costs savings