Problem

The client needed improving clarification in their thickeners for neutral leaching.

The super high molecular weight anionic reagent did not provide the required results.

The flocculant preparation was deficient because of the following reasons:

The super high molecular weight anionic reagent did not provide the required results.

The flocculant preparation was deficient because of the following reasons:

- Manual operation

- Lack of control in preparation concentration

- Clumping

- Insufficient time for reagent maturation

Solutions and results

We proceeded to evaluate and compare our ASFLOC anionic flocculants of low (N), high (SH) and super high (VHM) molecular weight, through laboratory tests. Our ASFLOC 024 SH was the reagent with which the best performance was obtained, reaching turbidities no greater than 13 NTU. With this the polymer part was resolved. To prepare the flocculant properly, and controlling its preparation concentration accurately, the following ASFLOC brand equipment was supplied:

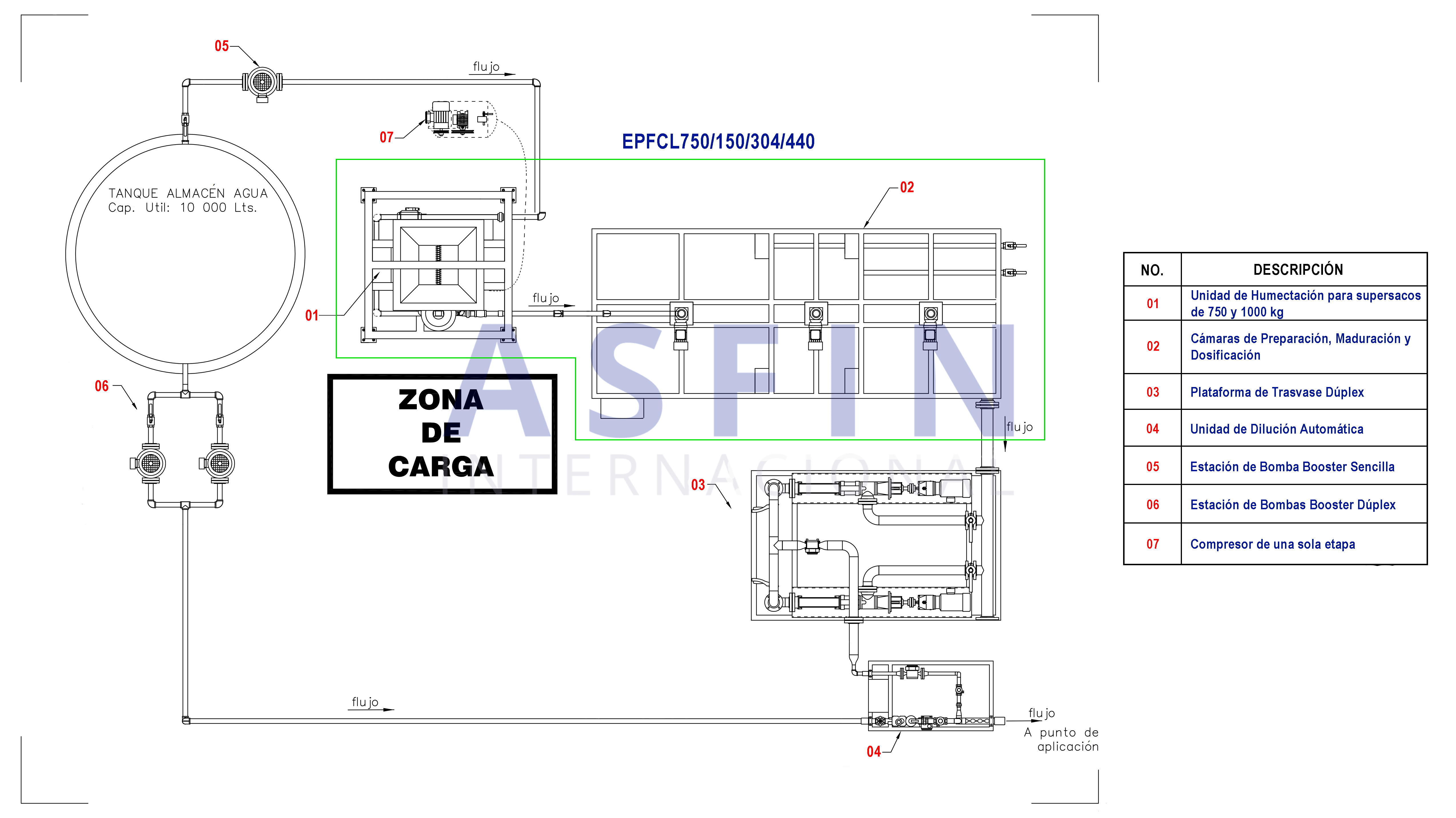

- A Flocculant Preparation Equipment model EPFCL750/150/304/440

- A duplex progressive cavity transfer platform model PDOS150/120 of 150 LPM

- An Automatic Dilution Unit model UDIL-AUT200 of 200 LPM

- A simple Booster Pump Station for water model EBB400/80 of 400 LPM

- A duplex Booster Pump Station for water model EBB400/80 of 400 LPM

- Single stage compressor with 5 CFM-80 PSI capacity

Since then, our client operates its neutral leach thickeners with high efficiency due to improved clarification and reduced consumption.

Note: The link of the equipment with the plant control room was also ensured, which allows simple and continuous operation.

Note: The link of the equipment with the plant control room was also ensured, which allows simple and continuous operation.

Benefits

- Better process control

- Reduction in reagent consumption

- Greater efficiency

- Continuous operation

- Automatic preparation, transfer and dilution of flocculant with remote monitoring

- Easy operation because only the polymer hopper needs to be filled

- Operating costs savings