About us

JL Goslar Anoden GmbH as a subsidiary of JL Goslar, created in 2014, has more than 60 years of experience in the development and production of “anodes for metal extraction”, a sector that has not stopped growing in recent years. . We have an advantage in terms of technical knowledge and are able to support clients efficiently from the start of their projects. We provide anodes for the extraction of Copper, Zinc, Nickel, Cobalt, Manganese or Cadmium, especially that can meet your specific needs. We also offer advice, variety of alloys, service, recycling and logistics. At JL Goslar Anoden GmbH we are increasingly dedicated to recycling used products. With the “Full-Service-Recycling-Programme”, an alternative is provided in the profitable manufacture of new anodes made of lead for the extraction of non-ferrous metals.

We offer

“Unmatched quality”

JL Goslar GmbH has manufactured anodes for the extraction of Zinc, Copper, Nickel, Cobalt, Manganese and Cadmium since the sixties supported by highly successful development, production and marketing. The prestige of the company culminated in the founding in 2014 of its subsidiary: JL Goslar Anoden GmbH in Ilsenburg, Germany. This meant being able to merge our technical knowledge in metallurgy, acquired over decades, with the production of anodes for electroplating.

Anodes are produced for all our customers around the world through the lamination process. Their outstanding features enable them to achieve longer lifespan, higher efficiency and lower energy consumption. They can be manufactured, with enormous precision, in any alloy and in the dimensions required, meeting the specific needs of each client.

We permanently pay enormous and meticulous attention to aspects related to safety, quality, economy, innovation and the environment. This is why our highly qualified staff feels so committed to recycling.

Technological tests and the constant exchange of information with scientific institutions and clients complement our experience and form a solid basis for personalized advice.

“Lead and Anode Recycling: A Win-Win Operation”

The recovery of used products is increasingly important. We are fully committed to this and wish to contribute strongly to sustainability thanks to our “green lead”.

When placing a new order, the customer can find out about returns and the transformation of the products used.

One component of improving customers’ value chain is our full-service recycling program for used anodes. These are processed and incorporated into our recycling process. Likewise, we can manufacture new lead anodes of the highest quality that guarantee obtaining ideal results for your electrolysis process; a situation in which we all save and win.

“Advice: Your partner at all times”

The requirements to improve the extraction of metals and the demand for specialized equipment for electrolysis continually increase.

That is why at JL Goslar Anoden GmbH we not only want to serve as a valued supplier, but also, based on our vast experience and skills, as a partner from initial contact to final delivery.

We can inform you about possible production methods, the advantages and disadvantages of each technology, its risks and costs. Likewise, we can provide advice on alloys and select together the one that best suits you.

This means the customer gets exactly the anode they require to meet their specific needs.

“Anode plate: Our lamination processes – Your benefit”

The anode plates and lead alloys are manufactured using the rolling processes developed at JL Goslar Anoden GmbH.

Compared to conventional cast anodes, there are advantages that make the electrolysis process more efficient and economical:

– Higher density

– Lower porosity

– Defined grain structure

– Less tendency to deform

– Greater conductivity

– Greater resistance to passivation

– Low oxygen due to overvoltage

As such, the laminated anode plate offers excellent corrosion resistance, deformation stability and energy efficiency. For customers, this means an anode with long life, higher productivity and lower operating costs. All production stages are carried out with the highest precision, attention and quality.

Upon customer request, we can also treat the anode plate surfaces with various pressure abrasive blasting processes. With this type of surface finish, we quickly achieve the formation of the necessary PbO2 and MnO2 layers.

The advantage: the anode reaches its full capacity in a very short time.

Likewise, all anode plates are manufactured according to the dimensions required by each client.

Our services also include cutting out the boards to increase current density and accommodate insulating spacers.

“Support bars: Manufactured based on the specific needs of each client”

The anode support rods, like the plates, are manufactured according to the individual requirements of each customer. After cleaning the copper rods, we apply tin and coat them with a few millimetres of molten lead.

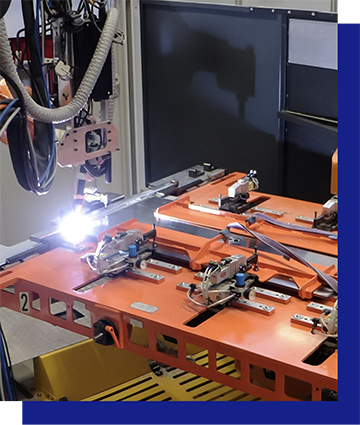

Our production process guarantees a perfect bond between the copper rod and the lead coating. This means that we can achieve corrosion protection from acid mist and optimum current flow for many years. The perfect bond between the plate and the lead-bonded copper support rod is achieved through an automatic soldering process on both sides of the anode.

“Specifically, our anodes offer the following benefits”

– Custom made lead alloys

– High density

– Defined grain structure

– Great resistance to deformation

– High resistance to the corrosion

– Rapid formation of PbO2 and MnO2 layers

– Lower energy consumption

– Long useful life

– Less stress on electrolysis cells

“Alloys: Just what your process requires”

In order for your project to achieve the best possible result when it comes to metal extraction, having anodes manufactured in the correct alloy is essential during downtime to avoid surface passivation.

At JL Goslar Anoden GmbH we offer many different alloys, such as PbAg, PbSbCaAl or PbSb. Our services include adapting our alloys for your anodes to the specific needs of your project. The benefits of a well selected alloy are:

– Resistance of the anode to passivation and corrosion

– Low oxygen due to overvoltage

– Increased electrical conductivity